Non-manufacturing costs are called period costs and are expensed in the period incurred. Distinguishing between the two categories is critical because the category determines where a cost will appear in the financial statements. As we indicated earlier, nonmanufacturing costs are also called period costs; that is because they are expensed on the income statement in the time period in which they are incurred. In the end, management should know whether each product’s selling price is adequate to cover the product’s manufacturing costs, nonmanufacturing costs, and required profit. As their names indicate, direct material and direct labor costs are directly traceable to the products being manufactured.

- In addition to indirect materials and indirect labor, manufacturing overhead includes depreciation and maintenance on machines and factory utility costs.

- Non-manufacturing costs include those costs that are not incurred in the production process but are incurred for other business activities of the entity.

- Distinguishing between the two categories is critical because the category determines where a cost will appear in the financial statements.

- For example, sales commissions and shipping costs for a specific product could be assigned to the product.

- For this Company, other direct materials would include, for example, plastic parts and paint.

Managerial Accounting

Costs that are not related to the production of goods are called nonmanufacturing costs23; they are also referred to as period costs24. These costs have two components—selling costs and general and administrative costs—which are described next. Examples of nonmanufacturing costs appear in Figure 1.5 “Examples of Nonmanufacturing Costs at Custom Furniture Company”. Manufacturing costs initially form part of product inventory and are expensed out as cost of goods sold only when the inventory is sold out. Non-manufacturing costs, on the other hand, never get included in inventory rather are expensed out immediately as incurred. This is why the manufacturing costs are often termed as product costs and non-manufacturing costs are often termed as period costs.

Effective Supply Chain Management and Logistics with ERP Systems.

- From this you can see that direct materials are the integral part and a significant portion of finished goods.

- Remember, though, that implementing ABC requires commitment and accurate data collection.

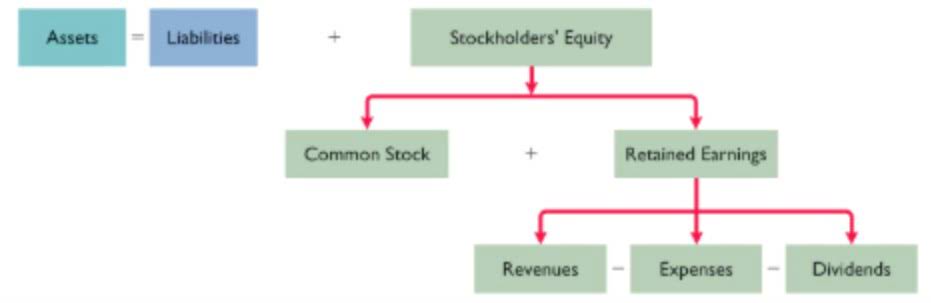

- The revenue that a company generates must exceed the total expense before it achieves profitability.

- Examples of one on one labor cost include labor cost regarding machine operators and painters within a manufacturing company.

- In this case, the management can decide to stop the production of some goods and invest in developing new ones that have a lower cost of production.

The first major category of nonmanufacturing https://onlyoneprinting.co/your-guide-to-a-complete-pro-forma-income-2/ costs encompasses all expenses related to soliciting customer orders and delivering the finished product. These selling and marketing costs begin the moment a manufactured item leaves the production floor and is ready for market distribution. Entities may manufacture several types of products and the sum total of all the costs involved in producing those products is termed as manufacturing cost.

Production Costs

The key aspect of nonmanufacturing costs is their mandated accounting treatment as period costs. This designation contrasts with manufacturing costs, which are treated as product costs and are capitalized to the inventory asset account on the balance sheet. Resources that become a fundamental portion of the finished product and that can be easily traced into it are called primary materials. For example wood is usually a direct material for that manufacturers of household furniture.

- The wood used to build tables and the hardware used to attach table legs would be considered direct materials.

- The wages paid to a construction worker, a pizza delivery driver, and an assembler in an electronics company are examples of direct labor.

- Optimize your workforce, take control of inefficiencies, and watch your profits soar with team time tracking software.

- The consulting firm was also able to re-negotiate the manufacturing company’s contracts with poor-performing suppliers.

- Indirect materials are materials used in the manufacture of a product that cannot, or will not for practical reasons, be traced directly to the product being manufactured.

Fluctuation of costs is yet another challenge that makes it harder to calculate manufacturing costs accurately, according to Fabrizi. Fabrizi also talked about the common challenges manufacturers face when calculating the costs of production. In his experience, the most common challenges are a lack of accurate data and the complexity of costing methods.

What are direct manufacturing costs?

By implementing these strategies and adapting them to your unique circumstances, you can effectively manage non-manufacturing costs and optimize your overall operations. In summary, Activity-Based Costing provides a more nuanced view of costs in service sectors. By focusing on activities and their drivers, organizations can make informed decisions, improve resource allocation, and enhance overall efficiency. Remember, though, that implementing ABC requires commitment and accurate data collection.

Non-Conformance Report process for Mid-Size Manufacturing Plant (Recommendations)

All these costs – marketing and sales expenses, G&A, and R&D – are non-manufacturing overhead costs. These costs aren’t directly related to the physical production of their devices but are essential to running the business and its long-term growth. nonmanufacturing costs include Examples of marketing and selling costs include advertising costs, order taking costs and salaries of sales persons etc. Examples of administrative costs include salaries of executives, accounting costs, and general administration costs etc.

Example #4: Indirect manufacturing costs (factory overheads)

Costs that are not related to the production of goods are called nonmanufacturing costs; they are also referred to as period costs. The wood used to build tables and the hardware used to attach table legs would be considered direct materials. Small, inexpensive items like glue, nails, and masking tape are typically not included in direct materials because the cost of tracing these items to the product outweighs the benefit of having accurate cost data. These minor types of materials, often called supplies or indirect materials, are included in manufacturing overhead, Foreign Currency Translation which we define later.